Wire sawing is an innovative method of cutting mass concrete structures and has opened up endless opportunities for the construction industry. Originating from an ancient technology used in-stone quarries, modern wire sawing of reinforced concrete came to the forefront in the early 1980’s. Although this technology is over 30 years old, there are only a small number of contractors that specialize in this technology. Di-tech has been an industry leader since bringing the technology to Canada in 1986, and has secured a number of methods and equipment patents. This furthers Di-Techs ability to provide our clients with the solutions to their mass concrete removal challenges.

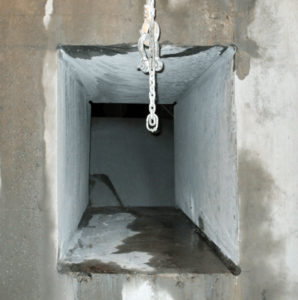

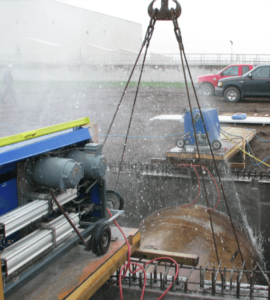

The diamond wire of the wire saw consists of an inner cable usually about a quarter of an inch in diameter. Fitted on this cable are beads with diamond grit, which are the cutting or chipping tools of the technology that have springs in between them to provide flexibility of the wire and projection of the inner cable. Some wires are coated with vulcanized rubber to provide protection for the spring and the inner cable. It also helps prevent the diamond beads from bunching or flying off the cable if it were to jam in the cut. The diamond cable is threaded through core holes, providing access for the wire to go through the concrete structure and the direction of the cutting plane. The ends of the diamond wire are hydraulically pressed together utilizing a joint press, creating a continuous loop. To begin cutting, the diamond wire saw then tensions the wire and the wire is spun at about 60 miles per hour, or 30 meters per second. The tension and rotation of the wire create a tremendous cutting force, enabling the wire to cut easily through the structure. This diamond wire can also be placed around the outer perimeter of an object where no core holes are required.

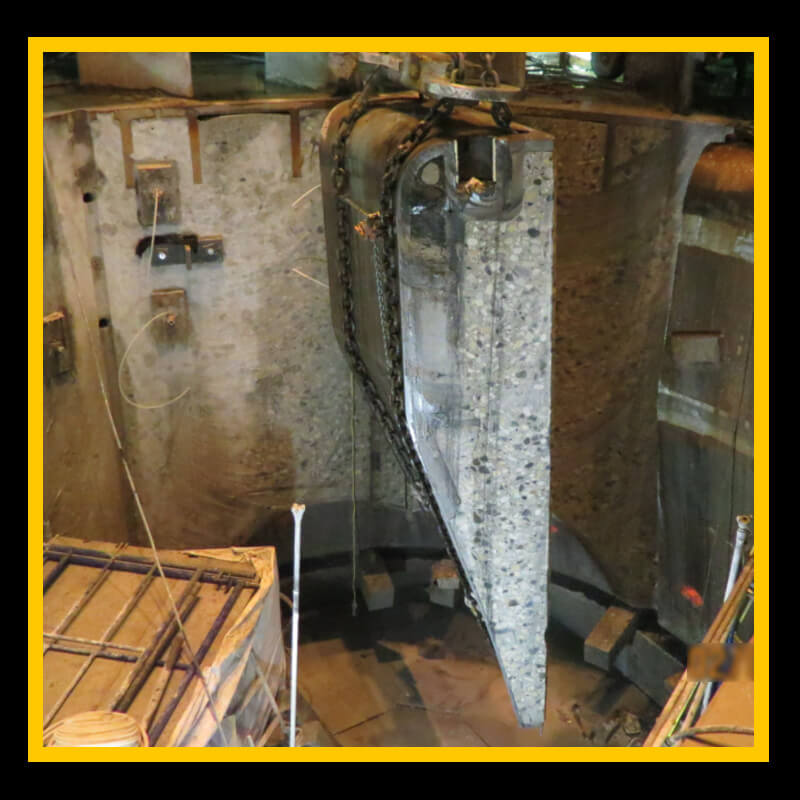

The only restriction to wire sawing is the imagination of the company that is offering the service. Wire saws have cut solid steel vessels, sectioned submarines underwater to be lifted to the surface, and have sliced through mass reinforced concrete sections weighing in excess of 100 tons. The wire saw is integral to projects where major modifications are performed and require the structural integrity to be maintained in the remaining structure.